Brewery

Behind the Scenes

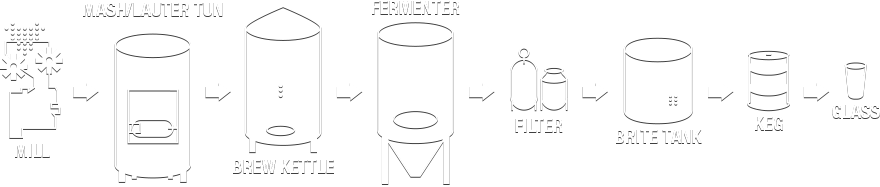

Our tried-and-true process for exceptional beer construction.

Perfection doesn’t come easy, folks! We have fine-tuned our process to ensure that the highest quality brew makes it to your glass. Believe us when we say that it wasn’t easy; but it sure was worth it.

Our Barrel Program

Something we celebrate every time a lucky batch of beer is chosen.

Generally, the beer has undergone the primary fermentation, where the yeast has consumed the vast majority of available sugars. The beer is then cold crashed, filtered and transferred to a selected barrel. Each barrel is evaluated on what spirit was previously stored in it, the variety of wood and toast of wood. All of these factors play into how the barrel and beer work together. After the barrel aging is complete (which can be anywhere from 3 to 18 months), the beer is then moved to either blending or packaging. For a select few beers, we will inoculate them with some crazy brett, pedio or lacto creatures. These different wild yeast strains will pick up where our standard beer yeast left off and begin eating sugars that were left unfinished. From this, the funk is born and the brilliance of a sour beer will shine through. This process is a slow one and will take anywhere from 6 to 24 months. However, great things come to those who wait.

Meet the Family

Bryce Shaffter

Bryce grew up in Iowa working in a tractor repair shop and went to college to study agricultural science but left with a business degree. All this experience came together once he started home brewing. He welded together his first brew stand and studied up on water composition and yeast propagation. After 5 years of brewing out of his basement, Bryce decided to take the leap into commercial brewing and one year later, Cinder Block Brewery was born.

Chandler Hottenstein

Chandler is originally from Chanute, Kansas but made her way to KC in 2018. She graduated from KU in 2015 and worked at 23rd Street Brewery in Lawrence, KS, as the front of house manager. We originally swooped her up as a bartender in 2018. Since then, she has moved her way up to Operations Manager and handles our marketing, as well. Interested in bar shifts, planning a party, or having an event? She's your go-to. Cinder Block's plant connoisseur!

Danny Kueser

Danny is originally from Louisburg, KS. He went to school at Pittsburg State for a BS in History. He has worked pretty much every job possible at Cinder Block. From bartending, to building the Reclamation Room, to brewing. He is now a full-time brewer and our cellarman. You can find him at the brewery most days of the week, pitching one of his many ideas. Part of the OG Cinder Block Crew!

Emily Yeager

Emily was previously at McCoy's Brewery working as their Assistant Brewer. She has been a great addition to back of house, along with Cinder Block as a whole! You can find her in the back; canning, washing kegs, and brewing. Look for her up front as well, working the bar and watching soccer games! Cat questions? She's your gal.

Michelle Pouppirt

Michelle is originally from Olathe, Kansas. After serving and bartending in several restaurants, she joined the craft beer industry in 2013 when she started at 23rd Street Brewery. She bartended at 23rd Street for eight years, and was even voted the 2nd best bartender in Lawrence in 2019! She enjoys live music, traveling, and spending time outdoors with her dog, Nala. Her favorite kind of cheese is string, and her favorite style of beer is sour or gose.

Chris Siliski

Chris is originally from upstate New York, but has spent most of his life in Kansas City, Missouri. Chris has been with Cinder Block since 2017 and worked his way from a food truck cook all the way to back-of-house beer production! Chris is passionate about computers, gaming, motorcycles, animals, and helping others. He likes many different beer styles, but if you know Chris, you know he's our biggest Cider fan! His love for Cinder Block began when he came in for a Weathered Wit for his 21st birthday, and the rest was history!

Angela Zurfluh

Angela went to the University of Nebraska-Lincoln where she graduated with both Environmental Sciences and Women and Gender Studies. She worked at a Vineyard and Cidery in Nebraska as a wine and cider maker for three years before moving to Kansas City with her husband, two dogs and cat. She is an assistant brewer here at Cinder Block. Outside of back of the house, she loves being at Beer festivals and chatting with other people in the craft beer industry. Loves creating playlists and listening to new music.